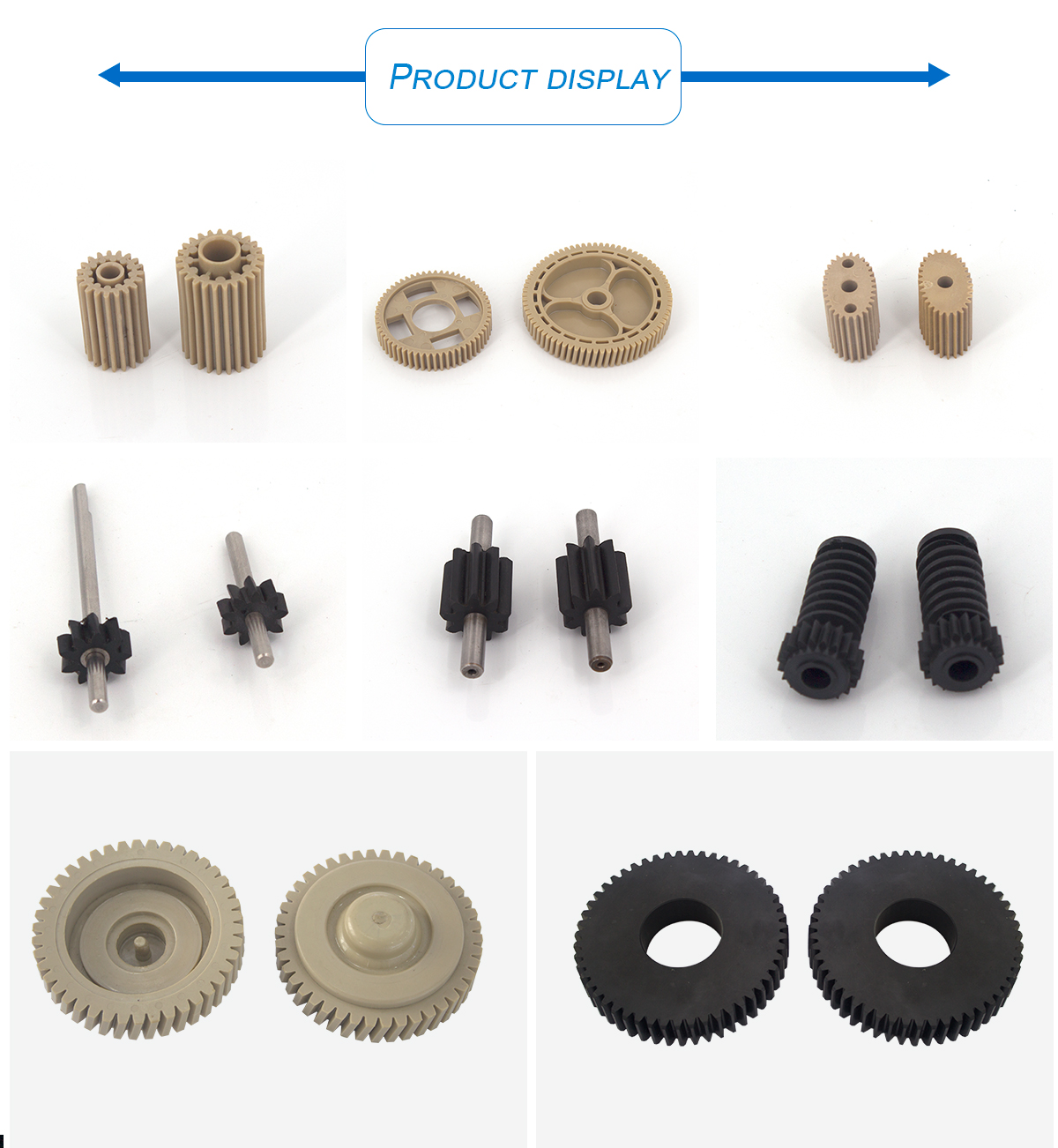

PEEK gear

advantages of PEEK gear: reduced noise, low density, light weight, decreased inertial distance, excellent chemical resistance, excellent resistance to grease and automobile fuel, low hygroscopicity, no expansion, weakening strength, high wear resistance, longer service life, better combination with metals and other plastics, reduced costs of injection molding. PEEK has the heat resistance, chemical stability of thermosetting plastics and the processing ability of thermoplastic molding. PEEK has a long-term service temperature of about 260-280℃, a short-term service temperature of 330℃, and high pressure resistance of up to 30MPa. It is a good material for high temperature sealing rings. PEEK products are suitable for all kinds of harsh working conditions in the environment. In addition, PEEK also has excellent properties such as good self-lubrication, easy processing, stable insulation and hydrolysis resistance, which makes it widely used in aerospace, automobile manufacturing, electrical and electronic, medical treatment and food processing and other fields.

400 178 2066

Introduce Parameter

-

-

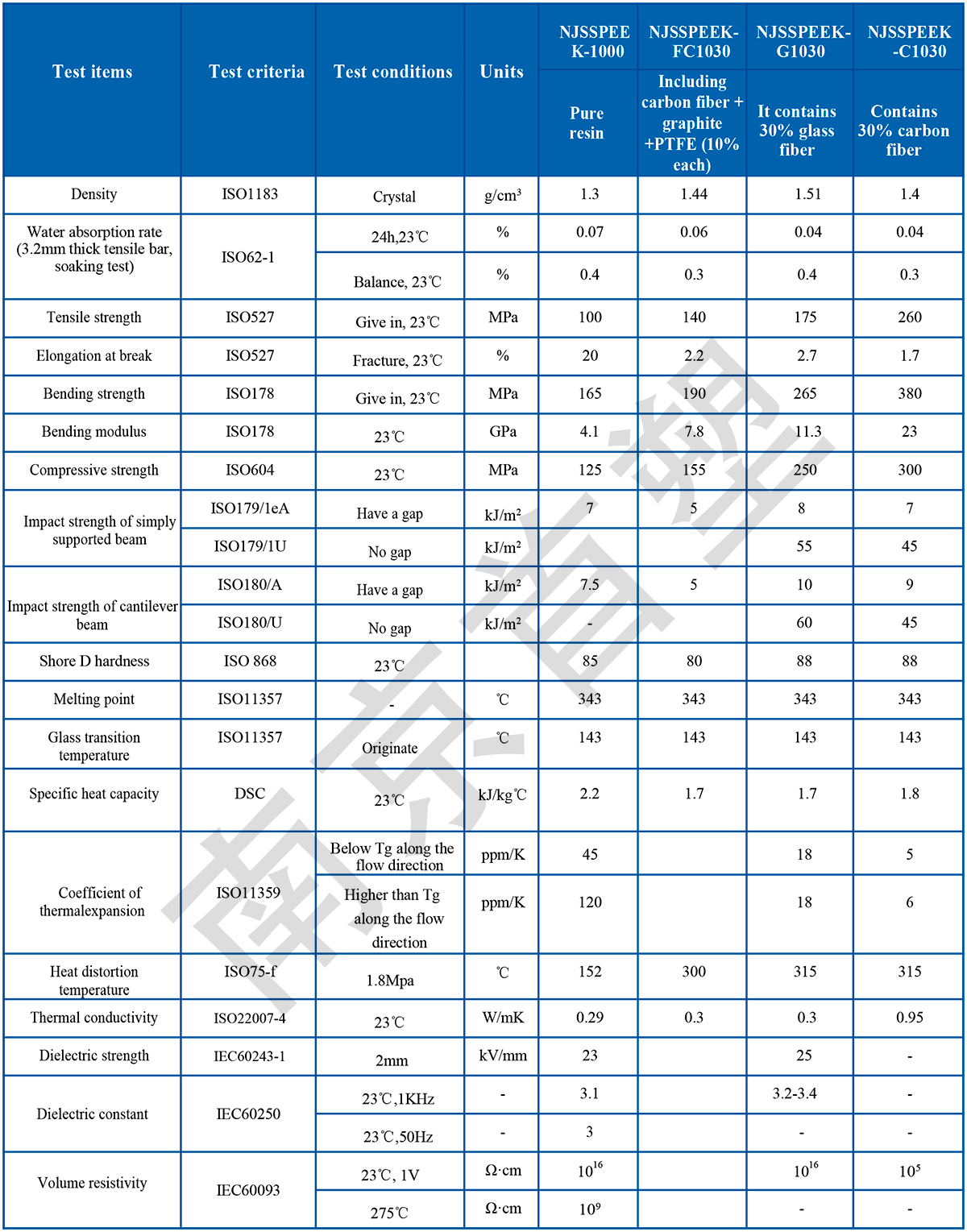

I.PEEK Performance Parameter Table:

to Top

to Top